Source: Vietnam Sourcing News

If you are going to use plywood for any development or do-it-yourself challenge it is best to know the fundamentals of the fabric. With wooden, a bit of data goes a great distance and maybe the distinction between a profitable and unsuccessful challenge.

What’s Plywood?

The only definition of plywood is a flat sheet of wooden veneers which have been bonded collectively. The phrase “ply” refers to plywood’s a number of skinny layers and comes from the French verb for “fold”, which is “plier”.

How is Plywood Made?

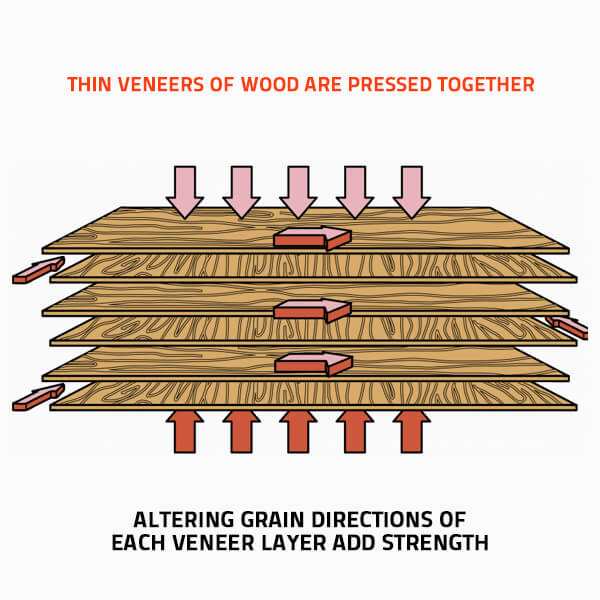

A type of engineered wooden (wooden derivatives which might be manufactured by binding or fixing resin and wooden fibre sheets collectively), plywood at all times has a minimum of three layers of veneers. Completely different tree species and glues are used to create completely different last merchandise, and in all circumstances, they’re completed with a bonding course of that includes warmth and strain.

The variety of layers, or plies, can also be at all times odd to correctly stability the sheet and cut back the danger of warping. The plies in some sheets could all be at proper angles to one another, or – if there are extra layers – they might be at stepped angles of 45 levels which provides power alongside a number of axes.

Both approach, this technique of alternating the angles of the grain is named cross-graining or cross-lamination and is what provides plywood its sturdiness and power. Cross-graining reduces wooden enlargement and shrinkage, improves dimensional stability, lessens the danger of splitting when the fabric is nailed at its edges, and makes the panel’s power constant in all instructions.

A Temporary Historical past of Plywood

Since plywood is so clearly manufactured and is used for a number of modern-day purposes – corresponding to large-scale cupboard constructing – lots of people suppose it is a comparatively new materials. That is an comprehensible assumption, but it surely could not be extra fallacious.

The method of cross-lamination to create a plywood-like materials is proven on a carving present in Thebes and relationship again to Historical Egypt! Historical Greece can also be recognized to have used this bonding method. In 1797 famous British naval architect and mechanical engineer Sir Samuel Bentham utilized for a number of patents for machines that produced veneers.

In his patent purposes, Bentham gave the primary written description of what we now know as plywood – he outlined the idea of laminating layers of veneer and glue to create a thicker piece. Roughly 50 years later. Nobel Prize creator Alfred Nobel’s father Immanuel noticed the potential of laminated wooden for trade.

Nobel Senior invented the rotary lathe, which is used, amongst different purposes, to show items of wooden and thus take away skinny sheets from them. Image peeling an apple with a pointy knife, and you have got a good suggestion of the method. An outline of rotary lathe veneer manufacturing was entered into an 1870 version of a French dictionary, so it is secure to imagine that this sort of manufacturing was established in France by that point.

Plywood made its strategy to the USA in 1865 and was utilized in industrial manufacturing shortly thereafter. The primary standard-sized sheets have been launched to the US markets in 1928, for use as a common constructing materials. By this level, the sheets have been now not thought of elegant and refined. Slightly than being related to elite, bespoke items they grew to become linked with low-cost mass manufacturing.

When water resistant, high-quality artificial glues have been invented within the twentieth century, plywood was given an entire new lease on life. Most importantly, it was important to the development of barracks, boats, weapons and even plane within the Second World Warfare. Geoffrey de Havilland’s well-known multi-role mosquito, usually affectionately referred to as The Picket Marvel, used the fabric for its wing surfaces, bulkheads, fuselage and different sections.

Plywood Varieties and is Functions

However let’s get again to the current; what’s plywood used for immediately?

Merely put, nearly something!

Relying on the kind of wooden and glue, together with the sheet’s grading, it may be all the things from a clean canvas alternative for artists to the fabric used for playground tools.

Softwood plywood, sometimes manufactured from Douglas fir, cedar, spruce, pine, fir or redwood, is right for development together with wind-bracing panels, flooring, roofs and partitions. As well as, it really works properly for fencing and automobile inside physique work, and to make packing containers and packaging.

Tropical plywood is principally provided by Malaysia and Indonesia, together with different nations in South-East Asia. Fabricated from combined tropical timber species, it is utilized in many on a regular basis purposes together with financial home development, construction panels and smaller do-it-yourself tasks.

Hardwood plywood is manufactured from dicot timber like Oak, Mahogany and Beech, and is used for particularly demanding environments. For example, heavy-duty flooring and partitions in factories, containers and transport automobiles are sometimes constructed from the fabric. Wind turbine blades and the insulation packing containers on liquified pure gasoline carriers are two different prime examples.

The correct, uniform thickness of hardwood plywood additionally makes it a best choice in die-cutting boards, high-end loudspeaker development, indicators and fences for outside promoting, sports activities tools, musical devices and furnishings.

Plywood Gradings

Plywood is graded in keeping with a number of variables. The grade can have a single letter, indicating the identical grade applies to the back and front, or two letters separated by a slash when the back and front are completely different grades. The grading system is printed under.

- A: Virtually free from all defects on each side.

- A/B: Face veneer is nearly fully defect-free; reverse veneers show a couple of discolourations or small knots.

- A/BB: Face veneer nearly good; reverse facet permits joints, giant knots and plugs.

- B: Veneers on each side have a couple of discolourations or knots.

- B/BB: A couple of knots or discolourations on face veneer; joints, plugs and enormous knots permitted on reverse facet.

- BB: Massive knots, plugs and jointed veneers are permitted on each side.

- C/D: A structural plywood grade meaning the face has filled-in defects and knots, whereas the reverse might need some which haven’t been crammed in. Neither facet has an look grade, and neither is sanded clean. Usually, the C/D grade is used for sheathing a constructing’s surfaces earlier than it’s coated with flooring, siding or one other product.

- WG: All damaged knots are plugged, however the one assure on this grade is that it has been properly glued.

- X: All defects together with cracks, knots and knotholes are permitted.

- WBP: Climate and Boil Proof plywood.

What’s WBP Plywood?

Climate and Boil Proof plywood is essentially the most sturdy sort, due to the melamine or phenolic resin utilized in its bonding course of. Since it’s so sturdy, WBP plywood is the one class that the United Nations Meals and Well being Organisation recommends with out reservation for exterior use.

The WBP score is a glue customary developed in the UK and set down in British Requirements Establishment customary 1203:1963. Phenolic resin WBP can face up to being submerged in boiling water for one to 3 days; melanin WBP can achieve this for 10 to twenty hours. The precise size of time relies on the grade of the wooden veneers and the glue getting used.

What’s Marine Plywood?

Marine-grade plywood shouldn’t be totally waterproof as its identify would possibly counsel, however its waterproof glue makes it extremely moisture and water resistant. Particularly manufactured from Douglas fir or Western larch, marine plywood could have knots, however won’t ever have knotholes. Light-weight-strong and nearly defect-free, it is good for outside furnishings tasks, particularly in coastal areas, boats and boat elements.

Benefits of Plywood

- Extremely versatile.

- Cut up edges on account of nails are decreased.

- Materials power is elevated.

- Minimal enlargement and shrinkage.

- Low threat of warping.

- Plywood furnishings is lighter to move than strong wooden items.

- Plywood is economical to make use of.

Disadvantages of Plywood

- Danger of long-term insect or water harm, though this may be minimised with a remedy to the veneers.

- Sculpting to surfaces shouldn’t be at all times straightforward.

- Not as sturdy as wooden.

- If not painted properly, the floor of plywood can peel off.

Make Certain Your Plywood is Reliable

As soon as you have determined what sort of plywood you wish to use, you are able to go! Simply be sure that is licensed as being ethically produced, with a seal of approval from the Forest Stewardship Council or different organisations that test the manufacturing sustainability.

Discover all the very best above-board plywood at Buildworld for tasks that you can be ok within each approach.